Liquid Painting Plants

Home / Liquid Painting Plants

Liquid Spray Painting Plants in India

Intech is a market-leading manufacturer and supplier of liquid painting plants in India. We offer plants in various ranges and technologies as per the unique requirements of our clients. Spray painting plants are designed according to space availability, size & shape of components, and painting methodology like electrostatic, airless, etc.

Intech provides booths in two types water wash and dry type. manufactured to meet international standards like OSHA, NEPA, CE our liquid painting processes are equipped with specialized paint kitchen to enable better paint mixing, quality and efficient paint recovery.

Benefits

Plants custom-designed as per requirements

Consistent supply of paint throughout the process

Quick colour change

Regulates proper quality & quantity of paint

Centralized fresh air unit

- Wash Water Type

- Dry type

- Paint Kitchen

- Selection Criteria

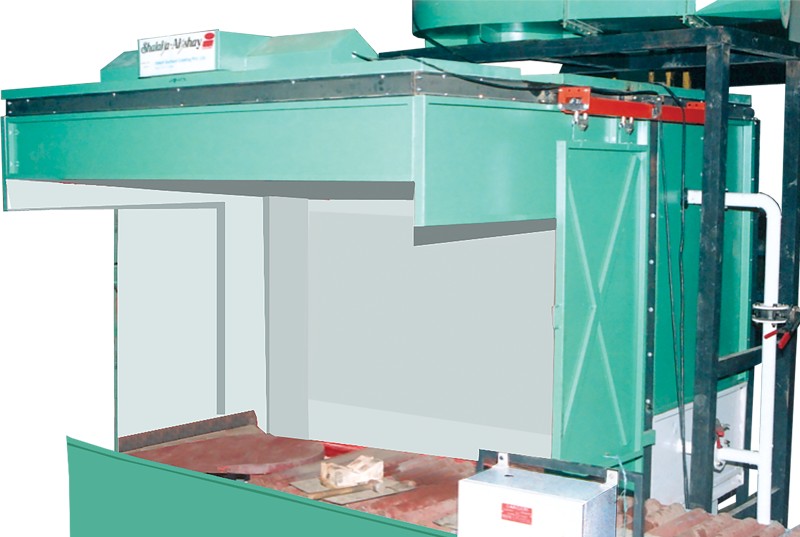

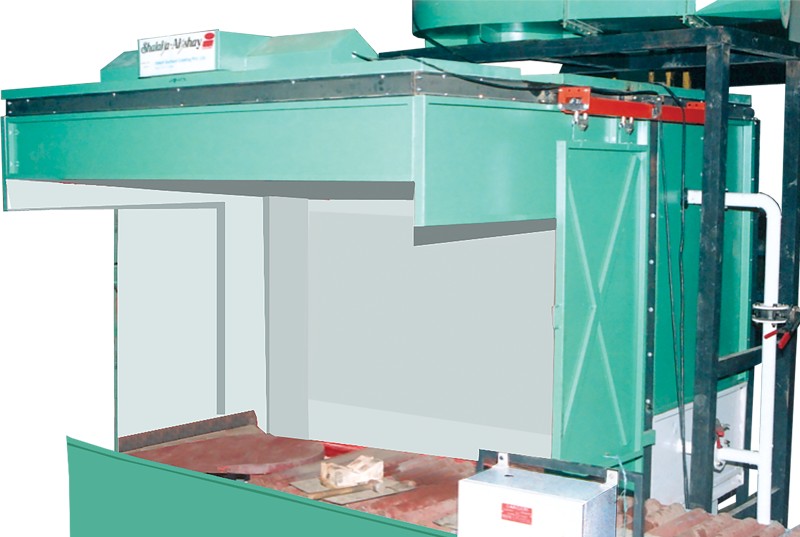

Wash Water Type

In the water wash type, two chambers are divided by a water curtain wall. The front spray chamber handles the painting process, while the Suction Chamber behind the water curtain efficiently separates paint particles from the air/thinner mixture. A top-mounted blower and motor enhance performance, showcasing the innovation in this advanced painting system.

Intech’s commitment to excellence is evident in the thoughtful design and integration of these essential elements, culminating in a liquid painting plant that not only elevates the quality of the end product but also prioritizes environmental responsibility.

Dry Type

In the dry back type, a notable departure from the water wash system occurs as metallic filters take the reins instead of a water curtain. This particular configuration proves advantageous in new paint lines characterized by lower consumption or in regions where water scarcity prevails.

The utilization of metallic filters serves a dual purpose: arresting oversprayed paint effectively and delivering a pristine air output to the atmosphere. This not only ensures the efficiency of the painting process but also positions the dry type booth as a sustainable solution, aligning with environmental considerations in the realm of industrial painting.

Paint Kitchen

Selection Criteria

Choosing the right booth type is contingent on various factors such as the size of the article, production scale, paint type and consumption, application method, and the number of operators involved. This nuanced decision-making process ensures that the selected booth aligns seamlessly with the specific requirements of the painting operation.

- Normally Dry Booth is recommended if paint consumption is low.

- A water Wash Booth is preferred when a higher volume of paint demands higher paint killing.

- The Down Draft version is needed for large/heavy articles so as to coat article from all sides.

- A side Draft booth is recommended for small articles.

- Combination Model – Side Draft/Down Draft: In scenarios with diverse and demanding production constraints, where articles range from 5 tons to 5 kg, Statfield provides an innovative solution. The combined side draft booth with down draft capability caters to the heavy production needs of various article types, ensuring adaptability and efficiency.

- For special applications where article size is very big, in the range of 6 meters, and if civil pit for the down draft is to be avoided, Statfield provides the option of sideward draft towards the bottom of the booth panel. Additional pressurization ensures dust free operation

Our Latest Blog

As industries evolve and expand, the need for scalable and efficient manufacturing processes becomes paramount. Powder

In today’s competitive market, businesses require reliable and efficient solutions to enhance their manufacturing processes. Powder

Unveiling the Secrets to Achieving Optimal Coating Quality Surface coating plays a pivotal role in numerous