Conveyors

Overhead conveyor for surface coating plants

Overhead chain conveyors stand out as the epitome of efficiency and convenience in material handling for surface coating plants. The impact of a meticulously designed conveyor system, coupled with a well-considered layout, cannot be overstated in enhancing the overall efficiency of a surface coating plant. Factors such as the production rate, available space, and the size and weight of the articles to be coated are pivotal in determining the most suitable conveyor system for optimal performance.

Types of conveyors are

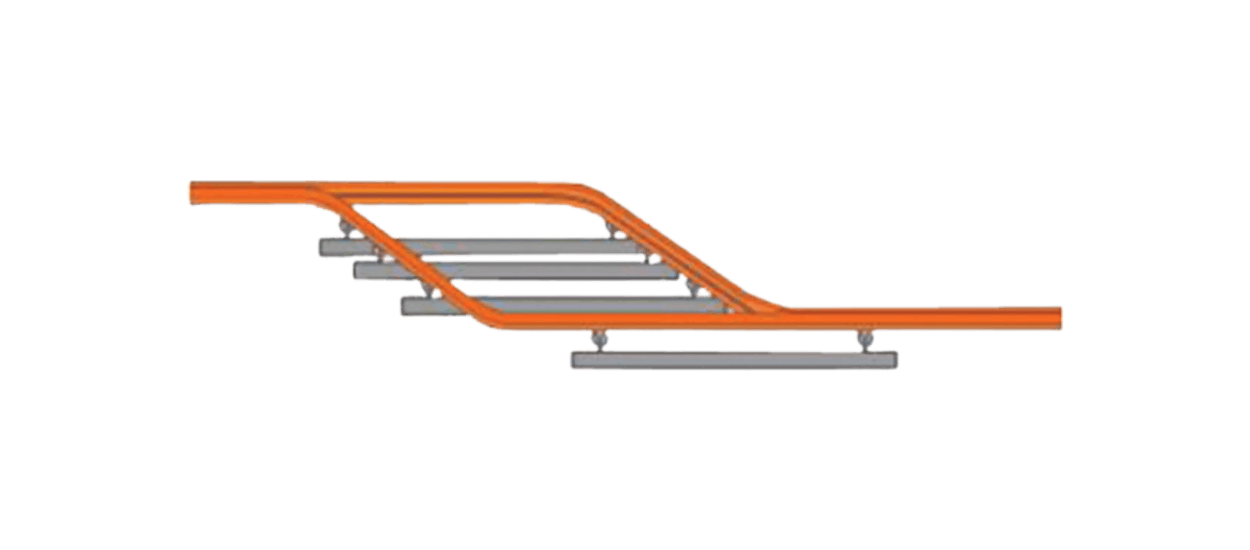

Free Track and trolley system for batch operation

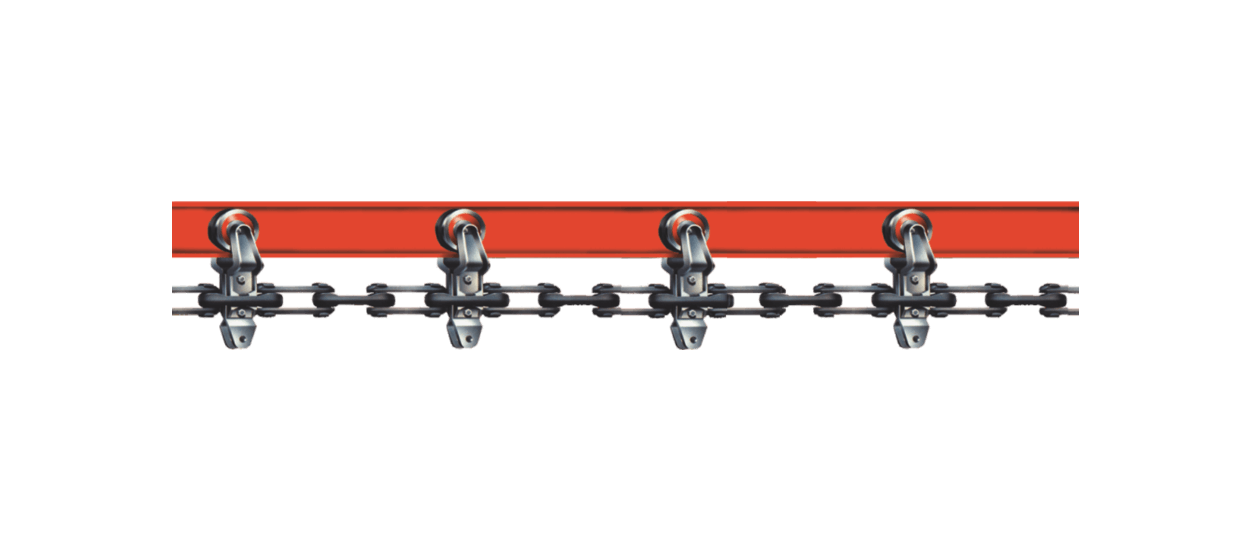

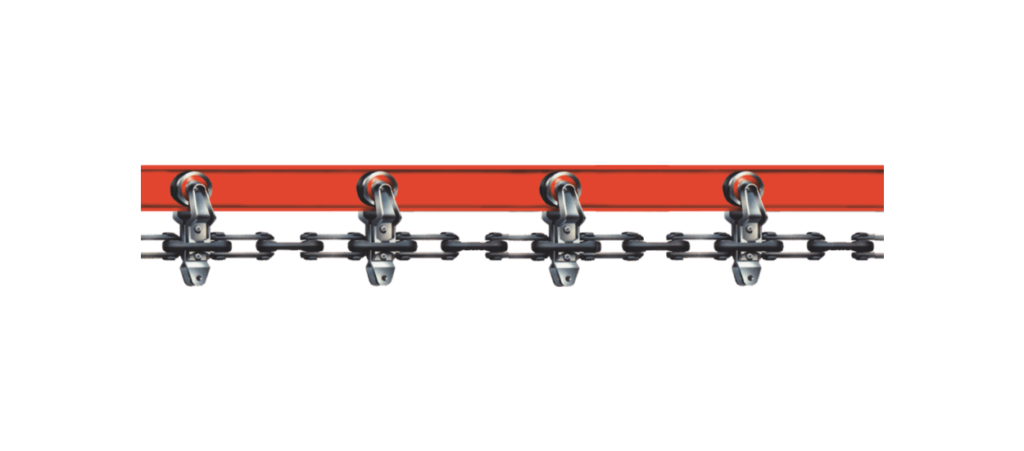

Mini-rail Overhead chain conveyors for lightweight articles

Aero-rail Overhead conveyors for medium-weight articles

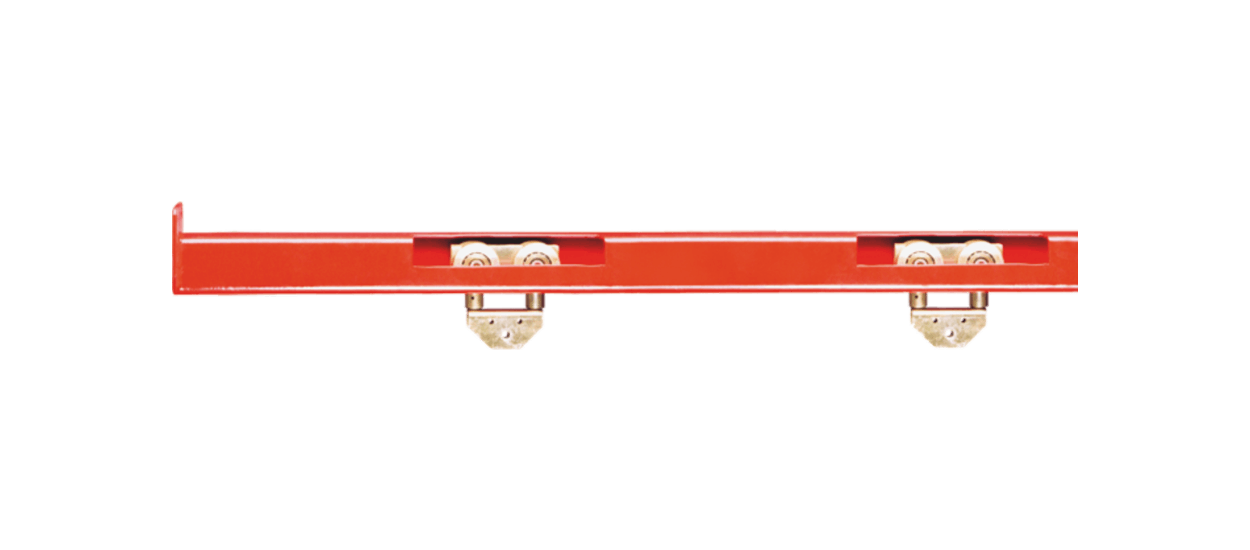

Heavy Duty I-Beam conveyor

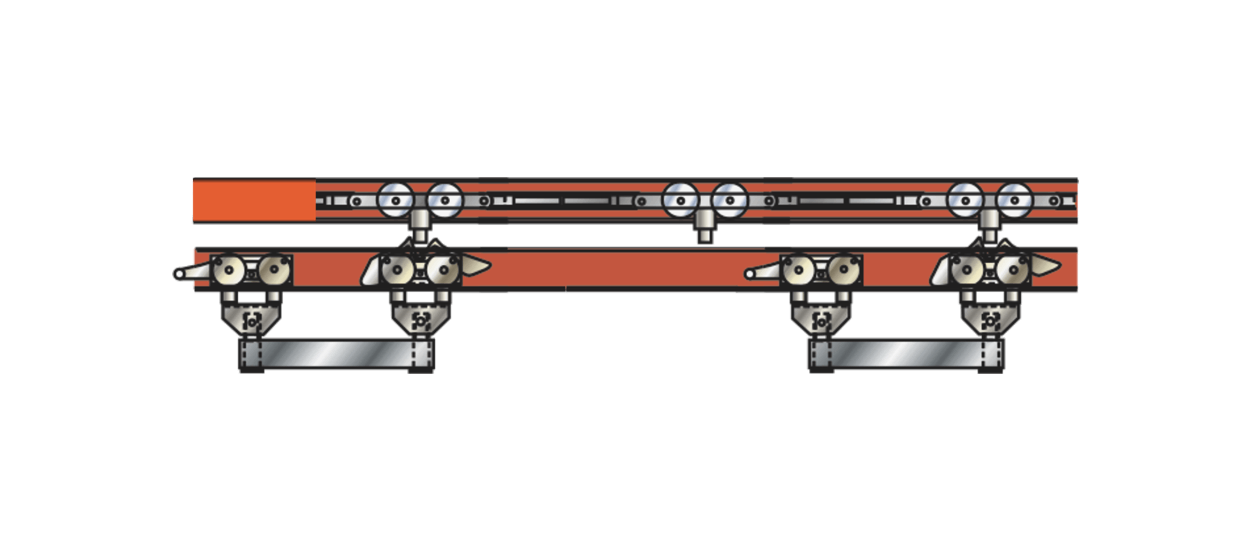

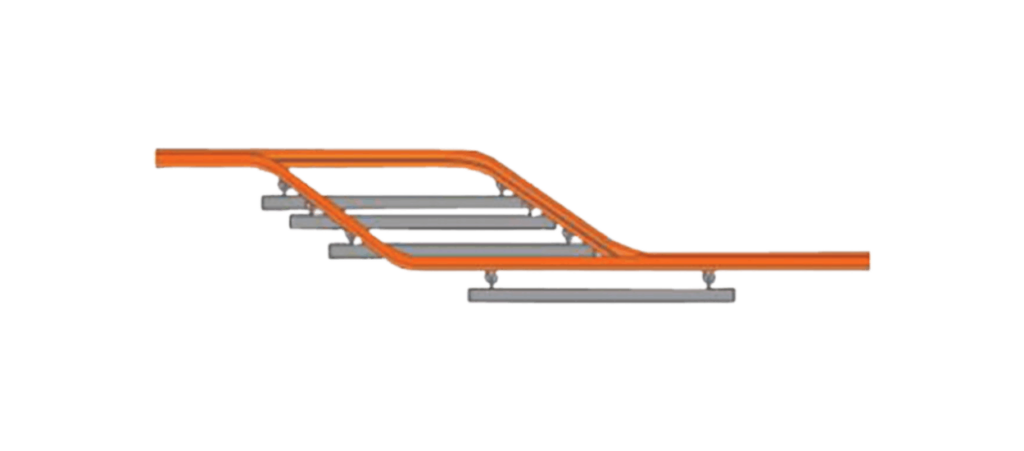

Power & Free Overhead chain conveyor systems

- Free Rail

- Aerorail

- Transrail

- Megarail

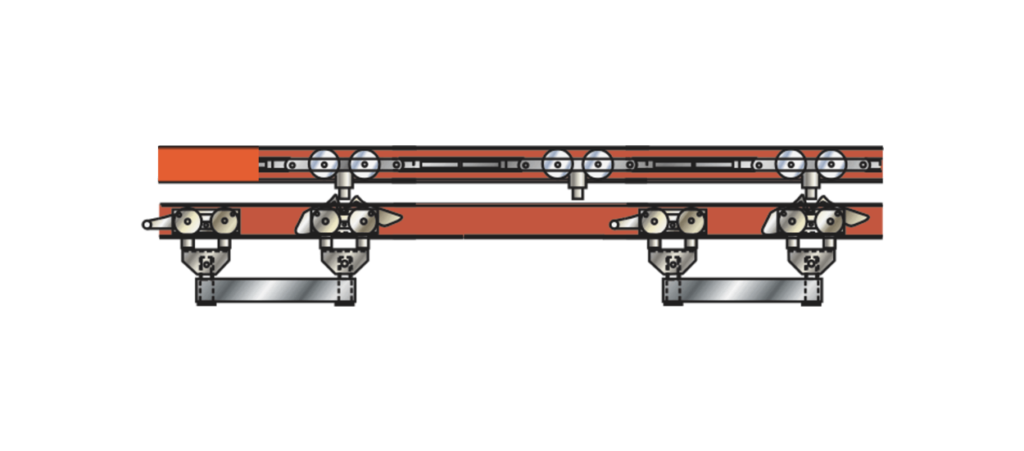

- Power and Free conveyor

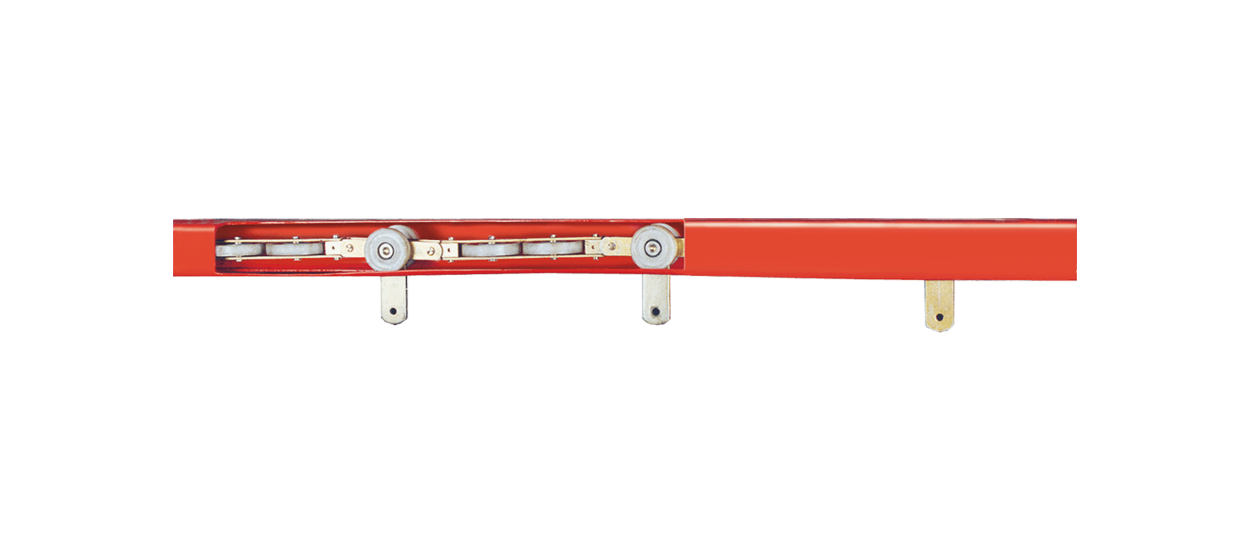

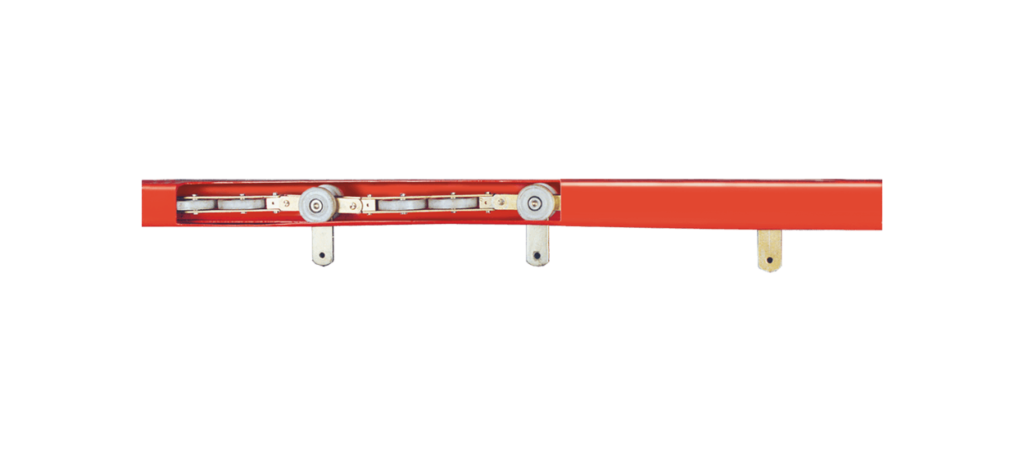

Free Rail

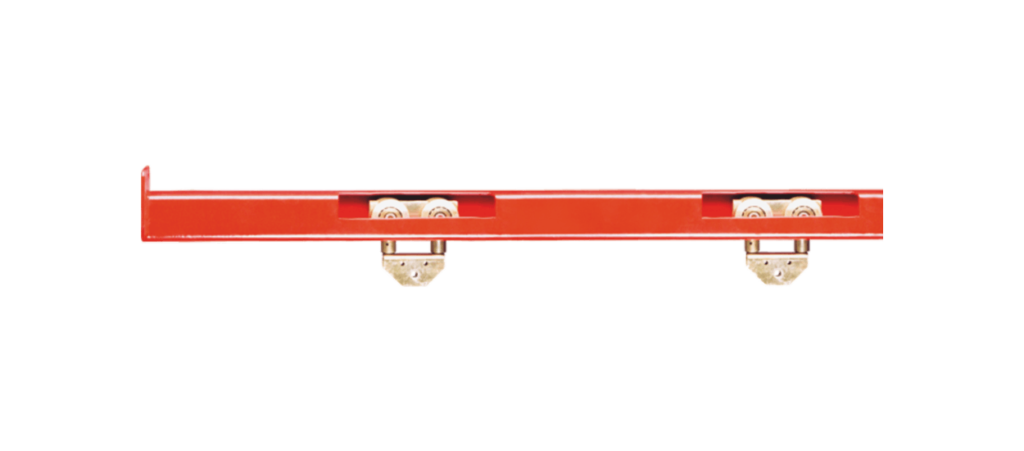

Aerorail

Transrail

Megarail

Power and Free conveyor

Our Latest Blog

When it comes to surface coating, Intech stands as a leading powder coating plant manufacturer in

Intech Surface Coating is a leading supplier of ovens for powder coating and liquid painting turnkey

When investing in a powder coating system, opting for a turnkey solution can offer numerous advantages.