Conveyors

Overhead conveyor for surface coating plants

Overhead chain conveyors stand out as the epitome of efficiency and convenience in material handling for surface coating plants. The impact of a meticulously designed conveyor system, coupled with a well-considered layout, cannot be overstated in enhancing the overall efficiency of a surface coating plant. Factors such as the production rate, available space, and the size and weight of the articles to be coated are pivotal in determining the most suitable conveyor system for optimal performance.

Recent Project

Material handling - conveyors in Food Industry

Material handling - conveyors

Benefits of conveyors

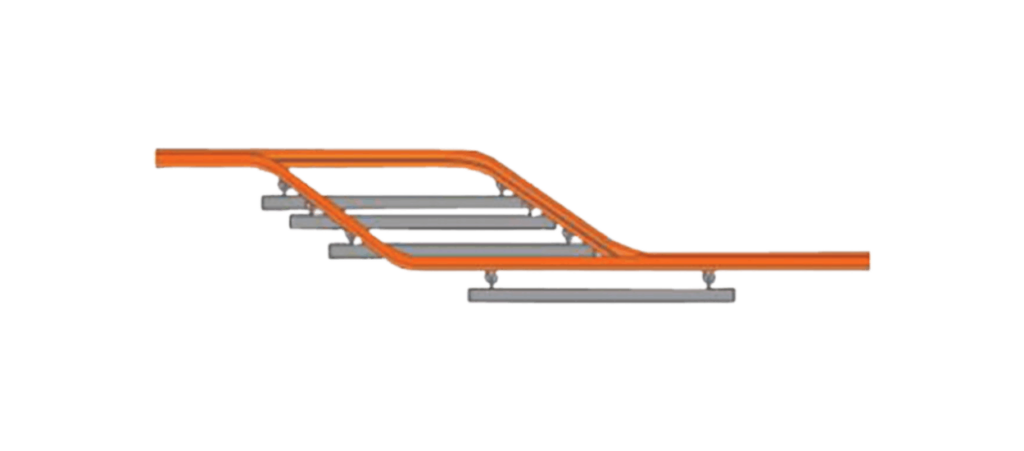

Free Track and trolley system for batch operation

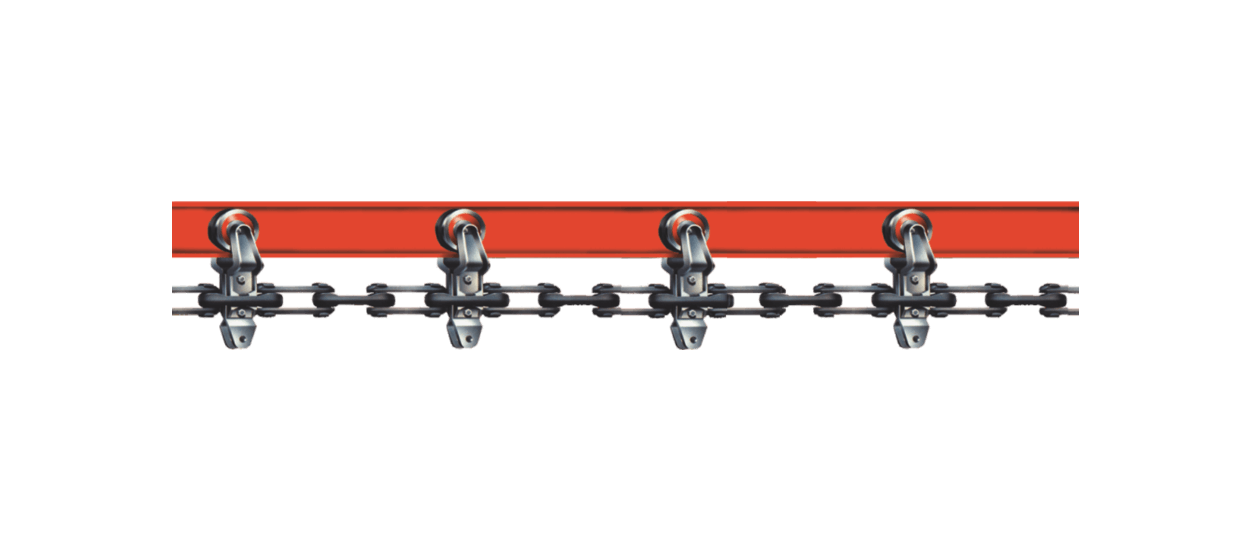

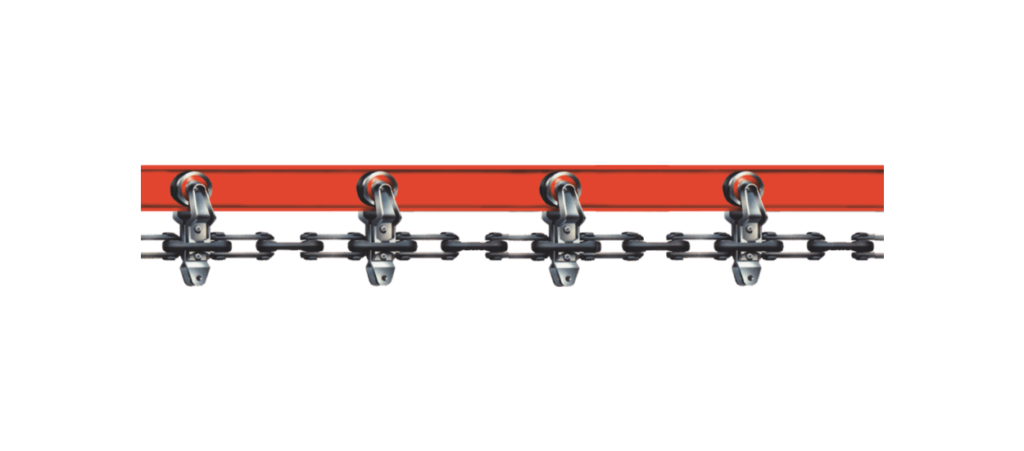

Mini-rail Overhead chain conveyors for lightweight articles

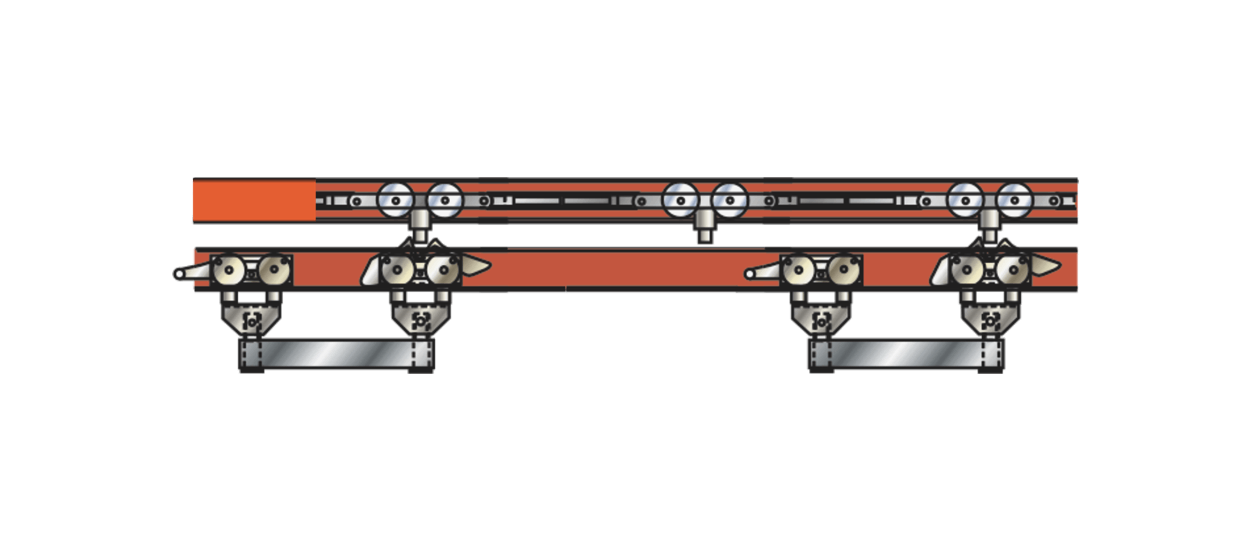

Aero-rail Overhead conveyors for medium-weight articles

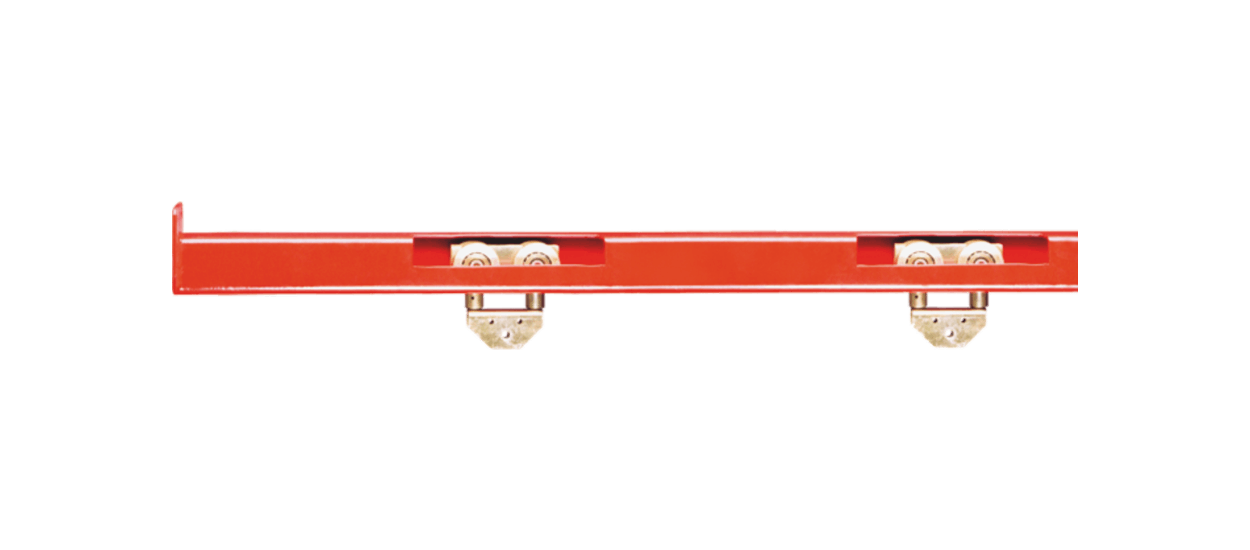

Heavy Duty I-Beam conveyor

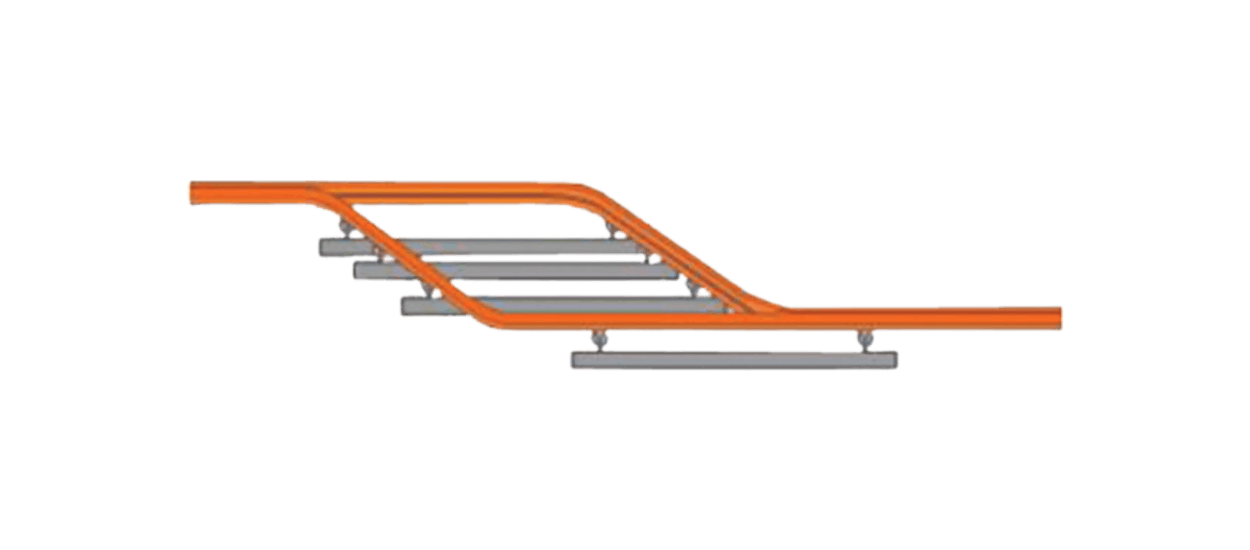

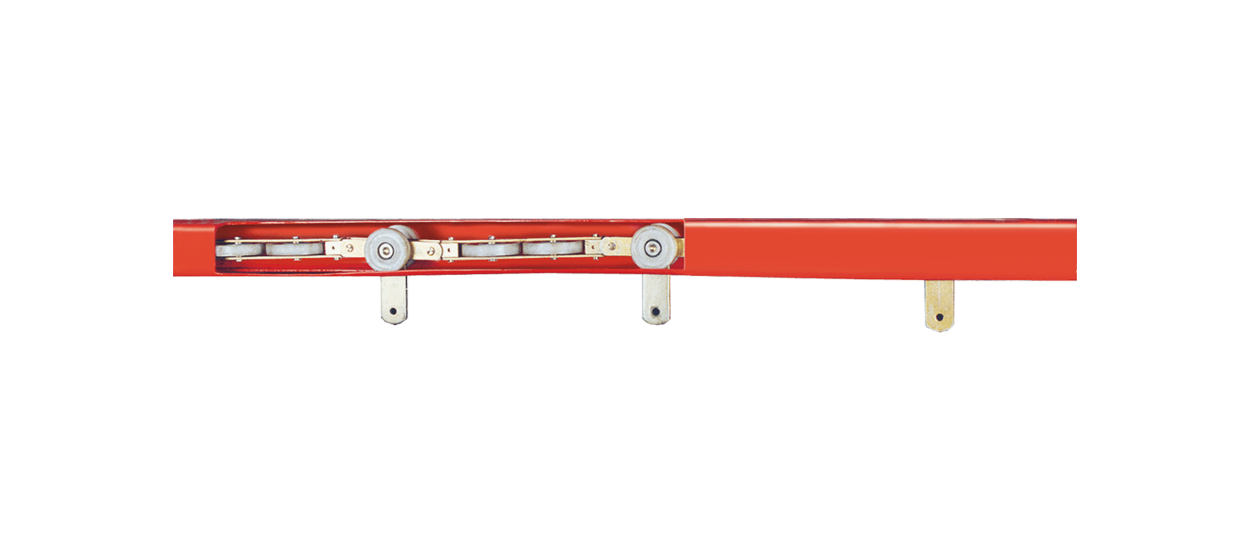

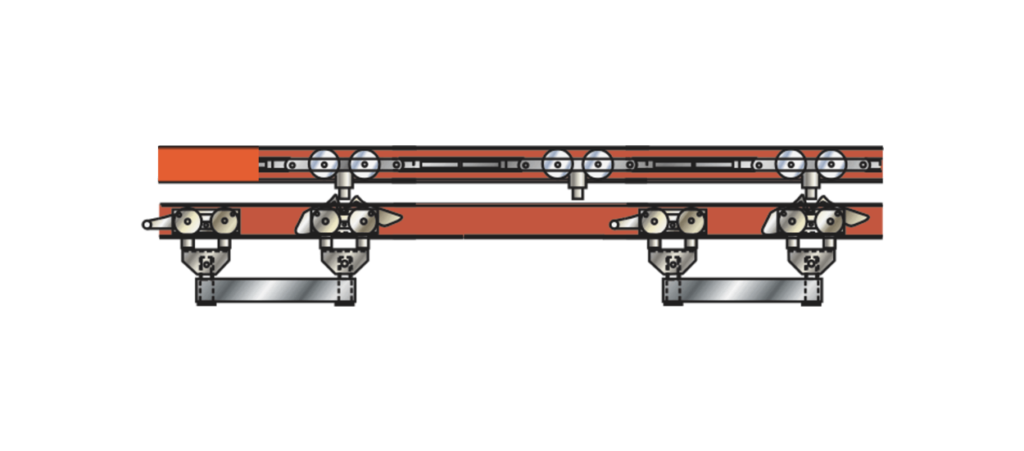

Power & Free Overhead chain conveyor systems

Types of conveyors

- Free Rail

- Aerorail

- Transrail

- Megarail

- Power and Free conveyor

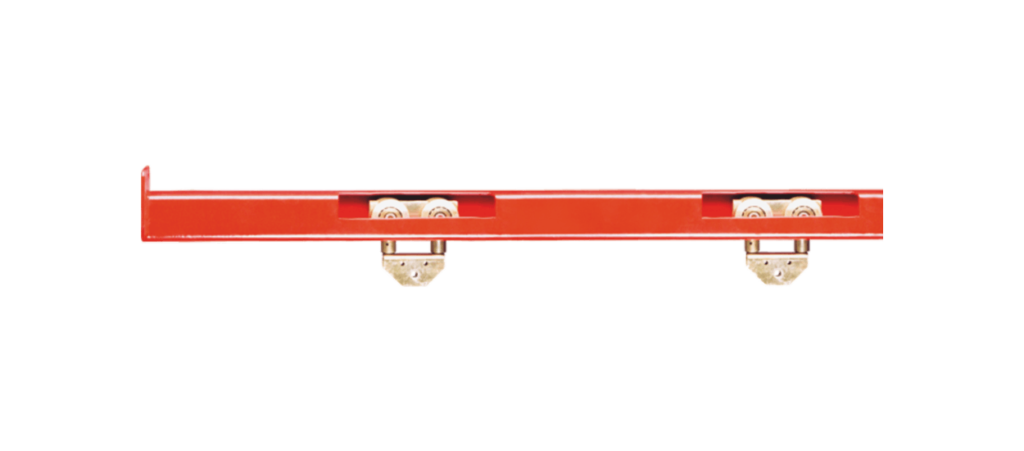

Free Rail

Aerorail

Transrail

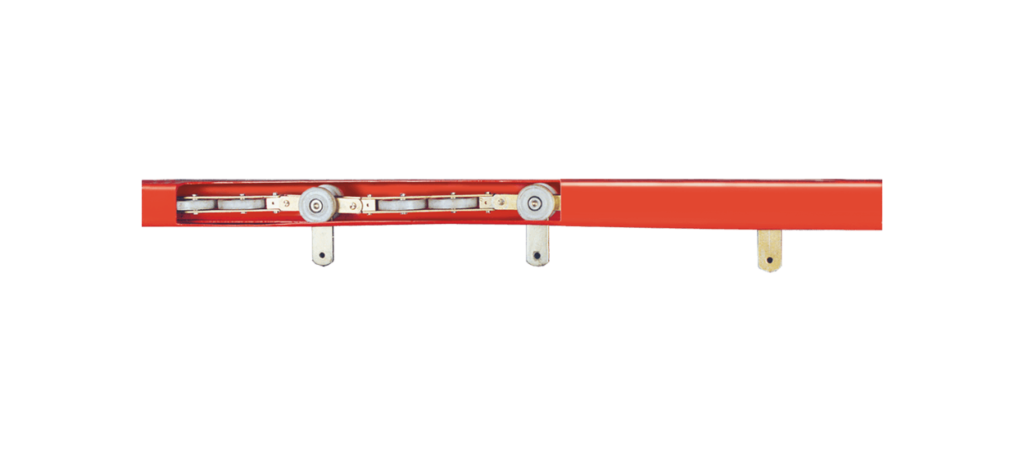

Megarail

Power and Free conveyor

Frequently Asked Questions (FAQs)

What is an overhead conveyor system in a surface coating plant?

It is a continuous chain-driven system where products are move or transport from location to location that ride on an overhead track. The conveyor transports products through the various stages of the surface coating process, such as pretreatment, drying, coating and curing ovens, in a precise and automated manner.

What are the main advantages of using an overhead conveyor for coating processes?

Maximized Floor Space: Frees up valuable floor space as the transport system is overhead.

Automation: Enables a fully automated production line, improving consistency and reducing labor costs.

Process Control: Ensures precise timing and speed through each stage (e.g., dwell time in oven).

Drip Collection: Ideal for wet painting, as it allows for proper drip-off and containment.

Handling Variety: Can be designed to handle a wide range of part sizes, weights, and geometries.

Is Intech overhead conveyor suitable for both painting and powder coating?

Yes, absolutely. Intech Overhead conveyors are the industry standard for both. The key difference is in the cleanliness requirements and the need for proper grounding (earthing) for powder coating to ensure electrostatic attraction.

How does an overhead conveyor compare to other types, like monorail or power-and-free?

Standard Overhead (Continuous): Simple, cost-effective, best for continuous flow where all parts follow the same path at the same speed.

Power-and-Free: More advanced. It allows for accumulation (stopping parts without stopping the entire line), switching between lines, and different speeds. This is ideal for complex processes or where buffering is needed.

What is an overhead conveyor system in a surface coating plant?

It is a continuous chain-driven system where products are move or transport from location to location that ride on an overhead track. The conveyor transports products through the various stages of the surface coating process, such as pretreatment, drying, coating and curing ovens, in a precise and automated manner.

What are the main advantages of using an overhead conveyor for coating processes?

Maximized Floor Space: Frees up valuable floor space as the transport system is overhead.

Automation: Enables a fully automated production line, improving consistency and reducing labor costs.

Process Control: Ensures precise timing and speed through each stage (e.g., dwell time in oven).

Drip Collection: Ideal for wet painting, as it allows for proper drip-off and containment.

Handling Variety: Can be designed to handle a wide range of part sizes, weights, and geometries.

Is Intech overhead conveyor suitable for both painting and powder coating?

Yes, absolutely. Intech Overhead conveyors are the industry standard for both. The key difference is in the cleanliness requirements and the need for proper grounding (earthing) for powder coating to ensure electrostatic attraction.

How does an overhead conveyor compare to other types, like monorail or power-and-free?

Standard Overhead (Continuous): Simple, cost-effective, best for continuous flow where all parts follow the same path at the same speed.

Power-and-Free: More advanced. It allows for accumulation (stopping parts without stopping the entire line), switching between lines, and different speeds. This is ideal for complex processes or where buffering is needed.

Our Latest Blog

In the industrial manufacturing, a product’s finish is its final defense and its first impression. For

Interested in discuss?

Intech is a leading manufacturer of Powder Coating Plant in Pune. We offers many Solutions for various industries.