Liquid Painting Plants

Home / Liquid Painting Plants in India

Liquid Painting Plants in India

Intech is a leading manufacturer, supplier and exporter of high quality Liquid Coating Plants, Liquid Painting Booths and Spray Painting Booths in all over world. We operate our advanced manufacturing facility in Pune, India, ensuring superior craftsmanship and delivering reliable solutions tailored to your needs.

We design our liquid painting plants and spray painting plants based on space availability, component size and shape and painting methodologies such as electrostatic painting, airless painting and more.

Liquid Painting Shop and Booths

Intech manufactures two types of booths water wash and dry type liquid painting solution. Our coating meets international standards like OSHA, NEPA, CE & more. We are specialized paint kitchens to ensure better paint mixing, superior quality, and efficient paint recovery.

Recent Project

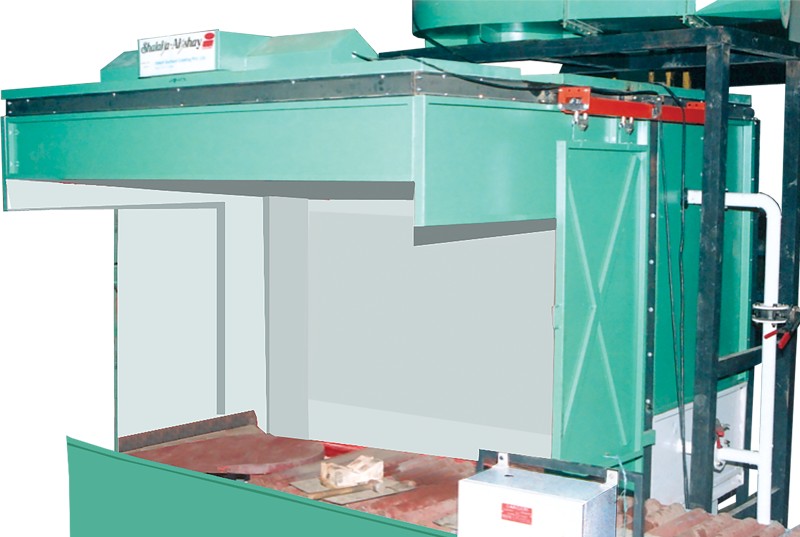

Electrostatic Liquid Painting - Dry back

Liquid paint booth - water wash type

Liquid-Painting-Plant-for-2-Wheelers-Sprocket-wheels-and-Engine-Components-1

Benefits of Liquid Painting Plant & Booths

Liquid Plant & Booth custom-designed as per requirements

Consistent supply of paint throughout the process

Quick colour change

Regulates proper quality & quantity of paint

Centralized fresh air unit

Types of Liquid Painting Plant & Booths

- Wash Water Type

- Dry type

- Paint Kitchen

- Selection Criteria

Wash Water Type

In the water wash type, two chambers are divided by a water curtain wall. The front spray chamber performs the painting process, while the suction chamber behind the water curtain efficiently separates paint particles from the air/thinner mixture. A top-mounted blower and motor enhance performance, showcasing the innovation in this advanced painting system.

Intech’s commitment to excellence is evident in the thoughtful design and integration of these essential elements, culminating in a liquid painting plant that not only elevates the quality of the end product but also prioritizes environmental responsibility.

Dry Type

In the dry back type, a notable departure from the water wash system occurs as metallic filters take the reins instead of a water curtain. This particular configuration proves advantageous in new paint lines characterized by lower consumption or in regions where water scarcity prevails.

The utilization of metallic filters serves a dual purpose:

arresting over sprayed paint effectively and delivering a pristine air output to the atmosphere.

This not only ensures the efficiency of the painting process but also positions the dry type booth as a sustainable solution, aligning with environmental considerations in the realm of industrial painting.

Paint Kitchen

This comprehensive system facilitates the seamless transfer and regulation of paint from the paint room to the applicator. It incorporates a pneumatic paint transfer pump designed for efficient paint and thinner transfer to the applicator. Stainless steel containers equipped with continuous operating pneumatic stirrers ensure consistent paint viscosity.

The distribution process, spanning from paint containers to feed applicators, involves precise control valves, ball valves, pressure regulators, paint filters, and non-return valves for all colors and thinner, complemented by return lines for optimal functionality.

Selection Criteria

Choosing the right booth type is contingent on various factors such as the size of the article, production scale, paint type and consumption, application method, and the number of operators involved. This nuanced decision-making process ensures that the selected booth aligns seamlessly with the specific requirements of the painting operation.

- Normally Dry Booth is recommended if paint consumption is low.

- A water Wash Booth is preferred when a higher volume of paint demands higher paint killing.

- The Down Draft version is needed for large/heavy articles so as to coat article from all sides.

- A side Draft booth is recommended for small articles.

Combination Model:

- Side Draft/Down Draft: In scenarios with diverse and demanding production constraints, where articles range from 5 tons to 5 kg, Statfield provides an innovative solution. The combined side draft booth with down draft capability caters to the heavy production needs of various article types, ensuring adaptability and efficiency.

- For special applications where article size is very big, in the range of 6 meters, and if civil pit for the down draft is to be avoided, Statfield provides the option of sideward draft towards the bottom of the booth panel. Additional pressurization ensures dust free operation

Frequently Asked Questions (FAQs)

What is a Liquid Painting Plant?

A Liquid Painting Plant is a specialized facility designed for the application of liquid coatings onto various surfaces. It integrates equipment such as paint booths, spray guns, curing systems and automation to ensure smooth, consistent and high-quality coatings for industrial products.

How does a Liquid Painting Plant improve product durability?

By applying coatings in a controlled environment, the plant ensures strong adhesion and uniform thickness, creating a protective layer that resists weathering, abrasion and chemical exposure extending product life.

What is the difference between Liquid Painting and Powder Coating?

Liquid Painting: Uses liquid paint with solvents or water-based mediums; suitable for heat-sensitive materials and offers a high-gloss finish.

Powder Coating: Uses dry powder cured by heat; extremely durable and environmentally friendly but not always suitable for all substrates.

Which industries can benefit from a Liquid Painting Plant?

Liquid Painting Plants are widely used in automotive, aerospace, furniture, appliances, electronics, construction, heavy machinery, and metal fabrication sectors. Essentially, any industry requiring high-quality surface finishing can benefit.

Is a Liquid Painting Plant environmentally friendly?

Yes, modern plants incorporate low-VOC paints, overspray recovery systems, solvent recyclers and energy-efficient curing methods to minimize impact on the environment.

Do Intech plants meet safety standards?

Yes, all our designs comply with international safety standards, including ventilation, filtration, and explosion-proof systems to protect workers and the environment.

Our Latest Blog

Powder coating is renowned for its durability and sleek finish, but like any protective layer, it

In industrial manufacturing, surface finishing is no longer just a final step it’s a critical determinant of product

Your oven may show 200°C. Your part may still be under-cured. That’s because oven air temperature

Interested in discuss?

Intech is a leading manufacturer of Powder Coating Plant in Pune. We offers many Solutions for various industries.