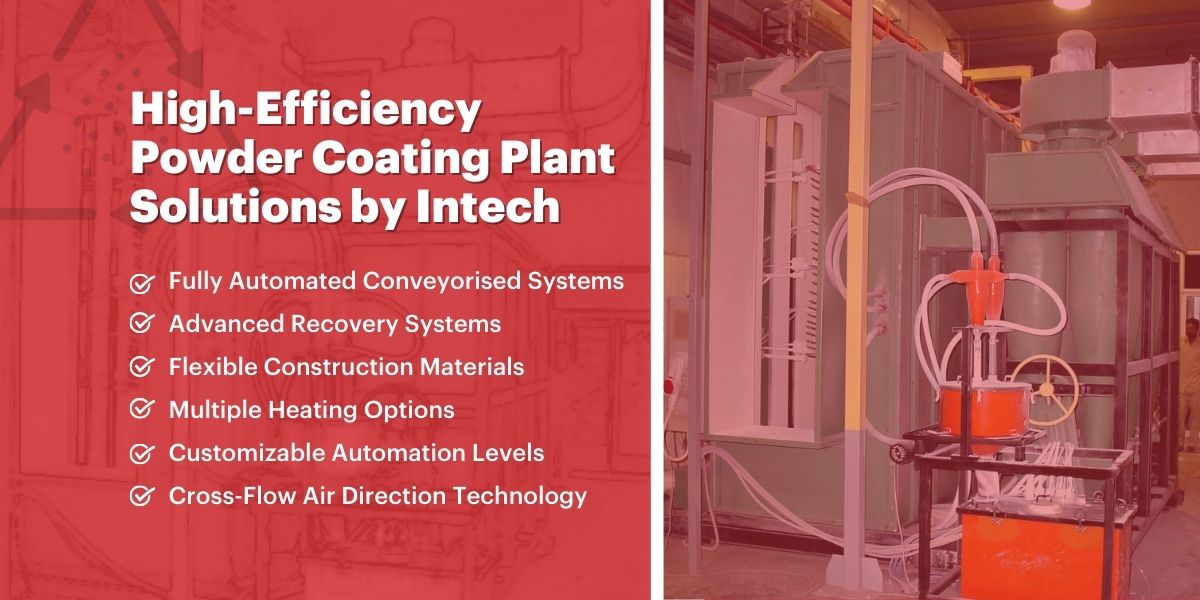

Premium Powder Coating Plants for Industrial Excellence

Intech delivers state-of-the-art powder coating plant solutions engineered for industrial manufacturers who demand superior finishing quality and operational efficiency. Our modular powder coating systems are custom-designed to meet the exact requirements of OEMs and large-scale job coaters across multiple industries.

Each powder coating plant we manufacture is precisely tailored to your specific production environment, considering available space, component substrates, required finishing levels, and other critical parameters. This customized approach ensures optimal performance for your unique manufacturing processes.

Key Features That Set Intech Powder Coating Plants Apart:

- Fully Automated Conveyorised Systems that streamline production and minimize manual handling

- Advanced Recovery Systems capturing up to 98.5% of powder for maximum material utilization

- Flexible Construction Materials including stainless steel, carbon steel, or composite materials

- Multiple Heating Options with gas, electric, infrared, or clean-heated air systems

- Customizable Automation Levels from semi-automatic to fully automatic configurations

- Cross-Flow Air Direction Technology for consistent, high-quality finishes

Our powder coating plants deliver exceptional value through superior surface finishing, enhanced product durability, and significant operational efficiency improvements. The modular design allows for future expansion and adaptation as your production needs evolve.

Technical Specifications:

| Specification | Details |

| Minimum Order Quantity | 1 Unit |

| Construction Materials | Stainless steel, Carbon steel, or Composite materials |

| Oven Heating Options | Gas, electric, infrared, or clean-heated air system |

| Automation Grade | Automatic & Semi-Automatic |

| Air-Flow Direction | Cross-Flow Type |

| Condition | New |

| Brand | Intech |

| Design | Customized to requirements |

Industry Applications:

Automotive & Transportation: Durable, corrosion-resistant finishes for vehicle components, bus parts, ship fittings, and aircraft elements

Furniture Manufacturing: Aesthetic, wear-resistant coatings for metal furniture and fixtures

Appliance Production: Consistent, high-quality finishes for consumer and commercial appliances

Architectural & Construction: Weather-resistant, long-lasting coatings for building components

Everyday Items: Durable finishes for functional products requiring superior protection

Ready to transform your finishing operations? Contact Intech today for a customized powder coating plant solution tailored to your specific manufacturing requirements.

Advanced Powder Coating Booth Systems

Intech’s powder coating booths represent the pinnacle of coating application technology, designed for maximum efficiency and minimal waste. Available in stainless steel, carbon steel, or composite materials, our booths are engineered to deliver consistent, high-quality finishes while optimizing powder usage.

The square chamber design, coupled with our multi-cyclone recovery system and powerful blower, creates an ideal environment for precise powder application. Each booth component works in harmony to ensure an efficient, optimized coating proces.

Superior Features:

- Carbon steel powder coated spray chamber with multi-cyclone recovery for nearly 100% powder utilization

- Maintenance-free design with exceptional operational lifespan

- Easy-clean configuration for quick color changes

- Safe operation with zero powder spillage outside the booth

- Maximum powder recovery for optimal material efficiency

- Compliance with stringent pollution control requirements

Whether you need a standard model or a customized solution for non-standard applications, Intech’s powder coating booths deliver exceptional performance across diverse manufacturing environments.

Elevate your coating quality and efficiency. Request a consultation to discuss your specific powder coating booth requirements.

Innovative Modular Multicyclone Technology

- Carbon steel powder coated spray chamber with multi-cyclone recovery for nearly 100% powder utilization

- Maintenance-free design with exceptional operational lifespan

- Easy-clean configuration for quick color changes

- Safe operation with zero powder spillage outside the booth

- Maximum powder recovery for optimal material efficiency

- Compliance with stringent pollution control requirements

Whether you need a standard model or a customized solution for non-standard applications, Intech’s powder coating booths deliver exceptional performance across diverse manufacturing environments.

Elevate your coating quality and efficiency. Request a consultation to discuss your specific powder coating booth requirements.

Innovative Modular Multicyclone Technology

The heart of Intech’s powder recovery system, our Modular Multicyclone delivers industry-leading efficiency of 98.5% with exceptional longevity. This advanced system significantly reduces operational costs while enhancing environmental compliance.

The high-velocity powder flow within the multicyclone minimizes powder sticking, virtually eliminating cleaning time and maximizing production uptime. This innovative design ensures consistent performance even in demanding industrial environments.

Key Advantages:

- Guaranteed 98.5% recovery efficiency for maximum powder utilization

- Extended operational life compared to conventional recovery systems

- Reduced maintenance requirements through advanced anti-sticking design

- Minimal cleaning time requirements for improved productivity

- Seamless integration with Intech powder coating booths and plants

Maximize your material efficiency and reduce waste. Contact our engineering team to integrate Modular Multicyclone technology into your powder coating operations.

Advanced Post-Filter Systems for Environmental Compliance

Intech’s post-filter systems complement our multicyclone technology, capturing the remaining 1.5% of powder fines to ensure complete compliance with environmental regulations. This critical component ensures that only clean, breathable air exits your powder coating operation.

Our post-filter design features multiple filter cartridges mounted inside a sealed metallic chamber. The filtration process occurs from outside in, with periodic purge cycles automatically removing accumulated powder and cleaning the cartridges. This self-maintaining design ensures consistent performance with minimal operator intervention.

Technical Highlights:

- 98.5% efficiency rating for comprehensive environmental protection

- Multiple filter cartridges in sealed metallic chamber

- Outside-in filtration process for optimal particle capture

- Automatic periodic purge system for self-cleaning operation

- Clean air output through blower outlet

Ensure complete environmental compliance. Speak with our technical team about integrating Intech’s advanced post-filter systems into your powder coating plant.

Frequently Asked Questions

Take Your Finishing Operations to the Next Level

Intech’s powder coating plants represent the culmination of decades of engineering expertise and industry knowledge. Our systems deliver superior finishing quality, exceptional durability, and outstanding operational efficiency across diverse manufacturing environments.

From automotive components to architectural elements, furniture to everyday items, our powder coating solutions provide the perfect finish for your products. With customized designs, advanced recovery systems, and comprehensive technical support, Intech is your ideal partner for all powder coating requirements.

Ready to discuss your powder coating needs? Contact our engineering team today for a personalized consultation and detailed quote tailored to your specific manufacturing requirements.