If you’re in the market for a reliable, high-performance customised powder coating booths, Intech Surface Coating offers a solution built not just for today but for long-term productivity, sustainability and precision.

With over 45 years of experience, Intech specializes in delivering turnkey powder coating plants that are custom built for both manual and automated operations. Based in Pune, India, we proudly serve across Sri Lanka, Bangladesh and the Gulf region, including UAE, Oman, Bahrain, Saudi Arabia and Egypt, offering end-to-end solutions from concept to commissioning.

What Makes Intech Customised Powder Coating Booths Stand Out?

At Intech, our modular powder coating booths are tailored to meet your exact production needs whether you’re coating small components or large fabricated structures. Our booths are constructed using:

- Stainless Steel (SS)

- Galvanized Iron (GI)

- Powder-coated Mild Steel (MS)

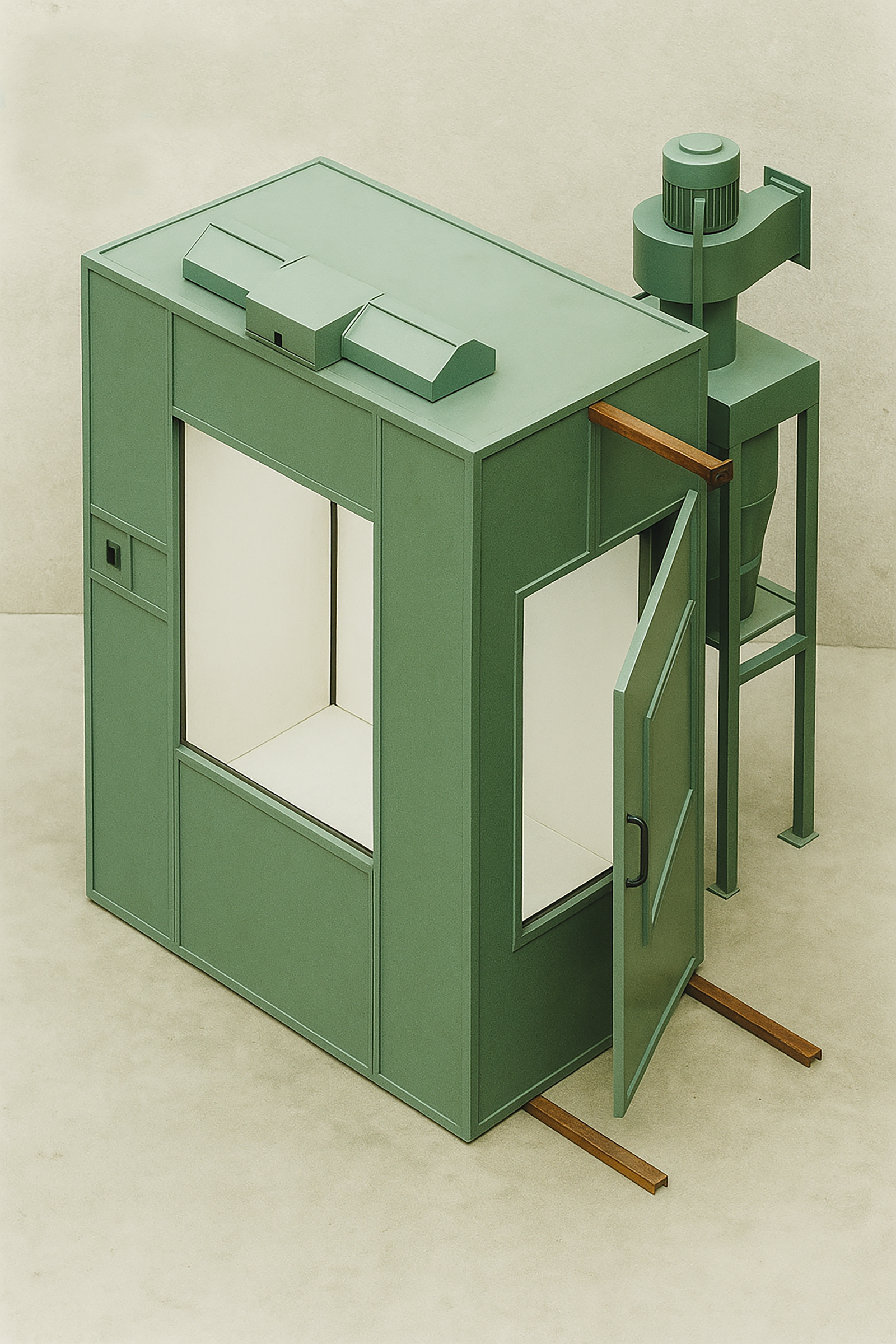

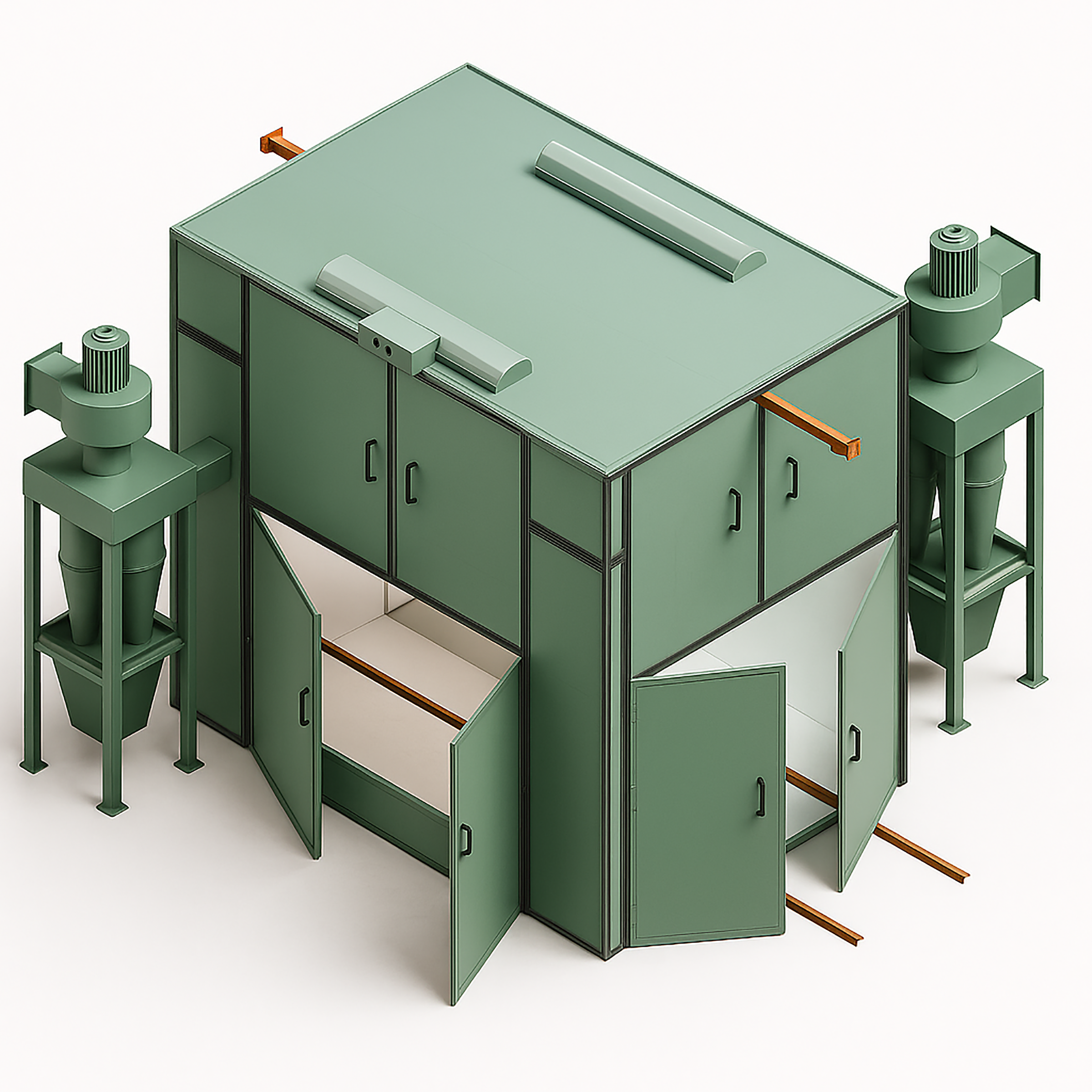

We offer a versatile range from compact front-loading booths to large-scale booths with side cut-outs and sliding door mechanisms for enhanced accessibility. We also provide loose track and trolley-based setups to streamline loading/unloading workflows.

How to Choose the Right Powder Coating Booth?

Selecting the right booth isn’t just about size it’s about fit. Here are the core parameters our engineering team considers during consultation:

- Size and shape of the component

- Weight of the article

- Expected production volume (powder consumption per hour)

- Efficiency of powder recovery

- Frequency of color changes

Whether you’re handling high-volume runs or specialty batches, we help you select a booth that maximizes output while minimizing material waste.

Medium Size Front Cutout. Slide loading facility

Specially for cupboards. Article can be loaded in the booth after mounting on trolley.

Specially for cupboards. Article can be loaded in the booth after mounting on trolley.

2 operator opposite to each others with doors. Both sides for the article can be used without reversing.

Advanced Powder Recovery Systems for Sustainable Operations

Multi Cyclone Powder Recovery System

Our powder booths are integrated with multi-cyclone recovery units that deliver up to 98.5% powder utilization. This means:

- Less material waste

- Lower operating cost

- Minimal powder spillage

The cyclone system automatically collects overspray powder and deposits it in a reusable bin, helping you maintain a clean environment and reclaim powder efficiently.

Post Filter System

While the multi-cyclone captures most of the powder, some ultra-fine particles (<0.5 microns) escape static charging. To comply with environmental norms, our post filters trap these particles and release only clean, breathable air through a high-efficiency blower.

We also offer bag filters made from non-woven filter media for capturing finer powder particles enhancing safety and reducing emissions.

Power Baking Ovens: Built for Consistent Curing

Our powder curing ovens are engineered to meet a variety of product geometries:

Each oven delivers uniform heating and airflow, ensuring durable finishes and faster turnaround times. Designed for continuous or batch operations, they’re built to keep your process efficient and controlled.

Benefits of Choosing Intech Powder Coating Booths

When you invest in Intech systems, you’re getting more than just equipment you’re gaining a production advantage:

- Modular spray booths for all types of applications

- Made with durable SS, GI or powder-coated MS materials

- Supports both automatic conveyor lines and batch type setups

- Quick powder recovery and easy maintenance

- Over 1,000+ installations worldwide

- Fully compliant with environmental and safety regulations

Ready to Build Your Customised Powder Coating Booths?

From consultation to commissioning, Intech Surface Coating is your trusted partner for a future-ready custom powder coating booth & setup. We design our systems for high efficiency, fast color changes, and long-term durability to give you a competitive edge in surface finishing.

Get in touch with our engineering experts to discuss your production challenges and explore a fully custom powder coating booth that fits your process like a glove.